As custom machined parts go through a wide range of processes to reach certain specifications, a variety of imperfections and issues can occur. It is crucial to inspect parts for any damage to ensure you get the best-machined part available; however, some forms of testing can damage a finished product. Thankfully, there is a solution, Liquid Penetrant Testing (Fluorescent Penetrant Inspection – FPI). Continue reading for a detailed look at FPI.

How Does FPI Work?

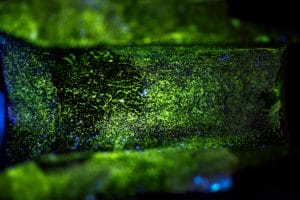

FPI is a liquid penetrant testing process that can check for machining defects without causing damage to the product. The main areas that FPI detects imperfections in are from machining, grinding, or forging processes. A fluorescent chemical is put onto the part’s surface, which can penetrate into textured areas and cracks. The part is then looked at under UV light, highlighting a contrast between the smooth surface and rough imperfections. By getting a clear visual between textures, our team is easily able to detect part irregularities.

Which Flaws Do FPI Commonly Detect?

Some marks that appear under UV light are just cosmetic flaws that have no impact upon your part. However, others may affect the strength and overall performance of your finished components. FPI is able to detect a wide list of common flaws including:

- Cosmetic defects

- Cracks

- Irregularities

- Porosity

- Seams

- Surface roughness

Are There Other Benefits of FPI?

Apart from FPI not harming components due to the process being a form of nondestructive testing, FPI also is a great form of inspection because it can efficiently inspect large quantities of parts with extreme accuracy. While some testing can only identify major surface issues, FPI can detect defects as small as hairline cracks. FPI is also highly versatile as the testing process can be used on most nonporous materials and for parts of nearly any shape or size.

While there are numerous testing processes available for machined parts, it is clear that FPI is one of the best and most efficient ways to test your parts. If you are looking for a company that performs FPI on their products, choose LPP! We can do FPI testing for virtually any industry’s hardware, and it is always performed according to ASTM E1417 standards. If you would like to learn more about the FPI process at LPP, check out our webpage here. Alternatively, if you have any questions, reach us by phone at (239) 643-LOOS (5667) or email at sales@loosnaples.com.